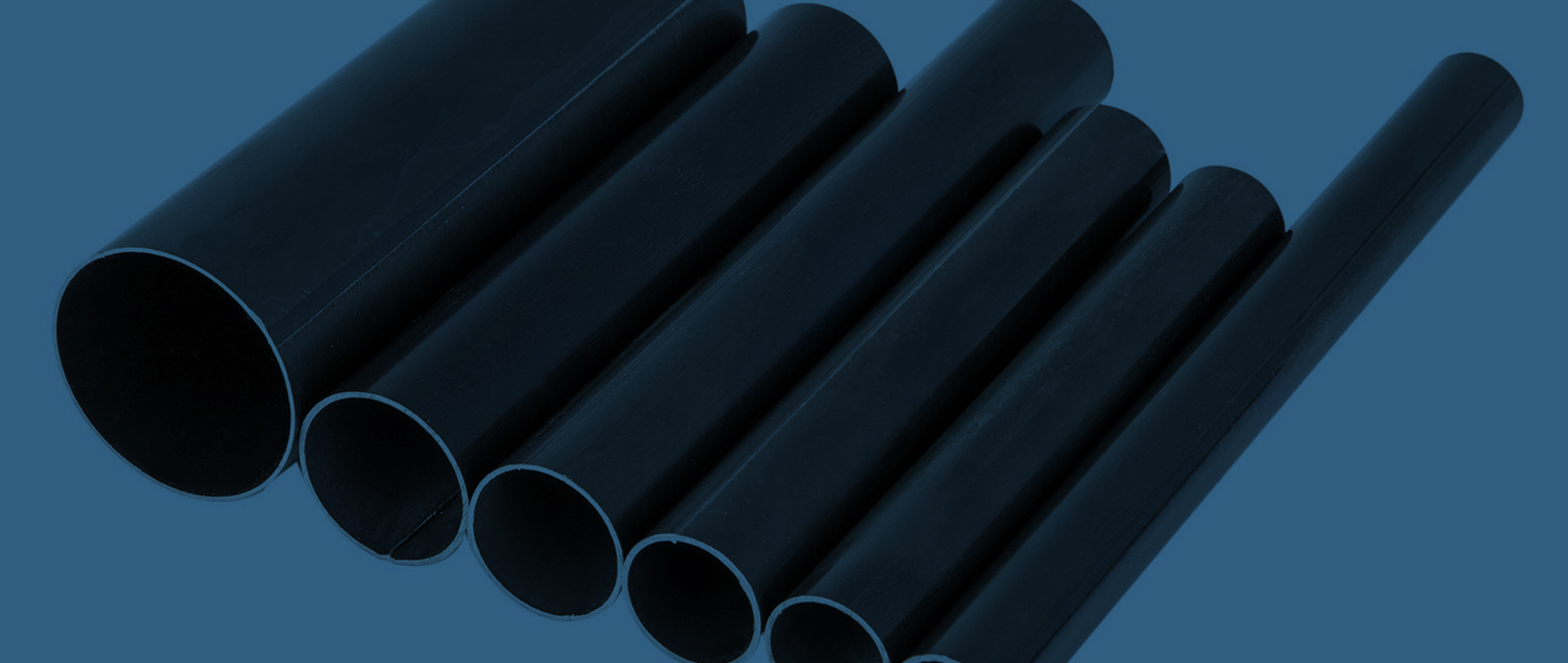

ERW Black Pipe

ERW Black Pipes are seamless steel pipes manufactured through the Electric Resistance Welding (ERW) process. They are highly durable, corrosion-resistant, and possess excellent mechanical properties. ERW Black Pipes are widely used in various industries due to their superior strength, versatility, and cost-effectiveness.

FEATURES

Material

ERW Black Pipes are made using MS Billets.

Size

ERW Black Pipes are available in a vast range of sized from

Standards

ERW Black Pipes conform to IS Standards and are also available in customer specifications.

APPLICATIONS

Structural Applications

ERW Black Pipes are ideal for structural applications due to their high strength and durability. They are commonly used in scaffolding construction for building and maintenance projects, providing a robust and reliable support system. Additionally, these pipes are used to create sturdy and secure fences for various purposes, including industrial, commercial, and residential applications.

Fluid Conveying Systems

ERW Black Pipes are widely used in fluid conveying systems due to their resistance to corrosion and pressure. They are suitable for water supply systems, both domestic and industrial, ensuring the safe and efficient transportation of water. Furthermore, these pipes are used in gas distribution pipelines, transporting natural gas and other gases reliably and efficiently.

Mechanical Engineering

In mechanical engineering, ERW Black Pipes find application in various hydraulic systems. Their strength and durability make them suitable for handling high-pressure fluids, ensuring optimal performance and longevity of hydraulic equipment.

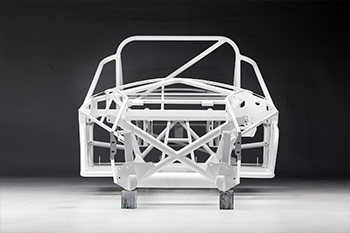

Automotive Industry

The automotive industry utilises ERW Black Pipes in the construction of vehicle chassis and frames. These pipes contribute to the overall structural integrity of vehicles while also aiding in weight reduction, improving fuel efficiency and vehicle performance.

Agricultural Applications

ERW Black Pipes are employed in agricultural applications, particularly in irrigation systems. Their durability and resistance to corrosion make them suitable for transporting water efficiently to crops. This helps optimise water usage and maximise crop yields, contributing to sustainable agricultural practices.

Oil and Gas

ERW Black Pipes are indispensable in the oil and gas industry. Their robust construction and corrosion resistance make them ideal for pipelines. These pipes efficiently transport crude oil, natural gas, and other petroleum products over long distances, ensuring a steady supply of energy resources.

QUALITY ASSURANCE

At every stage of production, we prioritise quality to deliver products and services that meet or exceed industry standards. Our commitment to quality assurance includes-:

Raw Material Inspection

Raw materials are thoroughly inspected to ensure quality is maintained.

In-Process Testing

Regular testing during the manufacturing process to verify adherence to specifications.

Final Inspection

Comprehensive quality checks on finished products, including dimensions, surface finish, and mechanical properties.

Certifications

Our products are certified in terms of quality and performance.

AFTER-SALE SERVICES

We are committed towards providing dedicated customer support at every stage of the purchase journey

Accountability

We assume full responsibility for any quality deficiencies and commit to prompt resolution.

Customer Support

Our dedicated support team is available to address any inquiries or concerns.

Choose Nirmal ERW Black Pipe for your diverse needs, knowing that it is a reliable, versatile, and performance-driven solution. With a commitment to quality, precision manufacturing, and comprehensive after-sale support, Nirmal ERW Black Pipe will meet and exceed your expectations in a wide range of applications.