MS Flats

MS Flats are versatile, rectangular mild steel bars, typically hot-rolled for a smooth, finished surface. They are available in a wide range of dimensions, measured in millimeters, catering to diverse applications. Known for their excellent machinability, weldability, formability, and malleability, MS Flats offer a balance of strength and workability.

FEATURES

Material

MS flats are made using MS Billets.

Size

MS flats are available in 50x25, 75x10, 75x12 mm

Standards

MS flats conform to IS Standards and are also available in customer.

APPLICATIONS

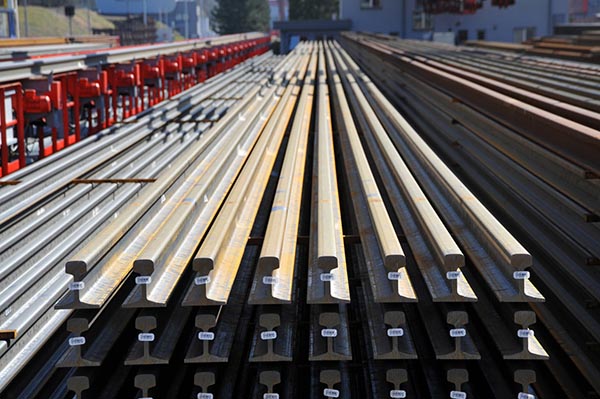

Railway Tracks

MS flats are used in the railway industry to construct strong and reliable railway tracks. These steel bars are used to create the sleepers, which support the rails and ensure smooth and safe train operations.

Construction Industry

MS flats are indispensable in the construction industry, serving as the backbone of numerous structural projects. Their robust nature makes them ideal for creating sturdy frameworks for buildings, bridges, and other infrastructure. Additionally, they are extensively used as reinforcement bars in concrete structures, significantly enhancing their strength and durability.

Mechanical Engineering

MS flats are widely employed in mechanical engineering to manufacture a diverse range of components. They are used to create machine frames, gearboxes, pulley systems, and other essential machinery parts. Moreover, these flats are indispensable in the construction of jigs, fixtures, and tooling, which are vital for precise manufacturing processes.

Automotive Accessories

MS flats are used to fabricate custom accessories for vehicles, like bull bars, side steps, and roof racks. These accessories enhance the vehicle's appearance and functionality.

Gym Equipment

MS flats are used to construct the frames of gym equipment, including weightlifting benches, racks, and cable machines. Their strength and durability make them ideal for such applications.

Fabrication Shops

Fabrication shops extensively utilise MS flats to create custom-made products and structures. These versatile steel bars can be easily shaped, cut, and welded to produce a wide range of items, including gates, railings, and architectural elements. Additionally, they are used to fabricate sturdy and durable furniture pieces like chairs, tables, and storage racks.

QUALITY ASSURANCE

At every stage of production, we prioritise quality to deliver products and services that meet or exceed industry standards. Our commitment to quality assurance includes-:

Raw Material Inspection

Raw materials are thoroughly inspected to ensure quality is maintained.

In-Process Testing

Regular testing during the manufacturing process to verify adherence to specifications.

Final Inspection

Comprehensive quality checks on finished products, including dimensions, surface finish, and mechanical properties.

Certifications

Our products are certified in terms of quality and performance.

AFTER-SALE SERVICES

We are committed towards providing dedicated customer support at every stage of the purchase journey

Accountability

We assume full responsibility for any quality deficiencies and commit to prompt resolution.

Customer Support

Our dedicated support team is available to address any inquiries or concerns.

Choose Nirmal MS Flats for your diverse needs, knowing that it is a reliable, versatile, and performance-driven solution. With a commitment to quality, precision manufacturing, and comprehensive after-sale support, Nirmal MS Flats will meet and exceed your expectations in a wide range of applications.