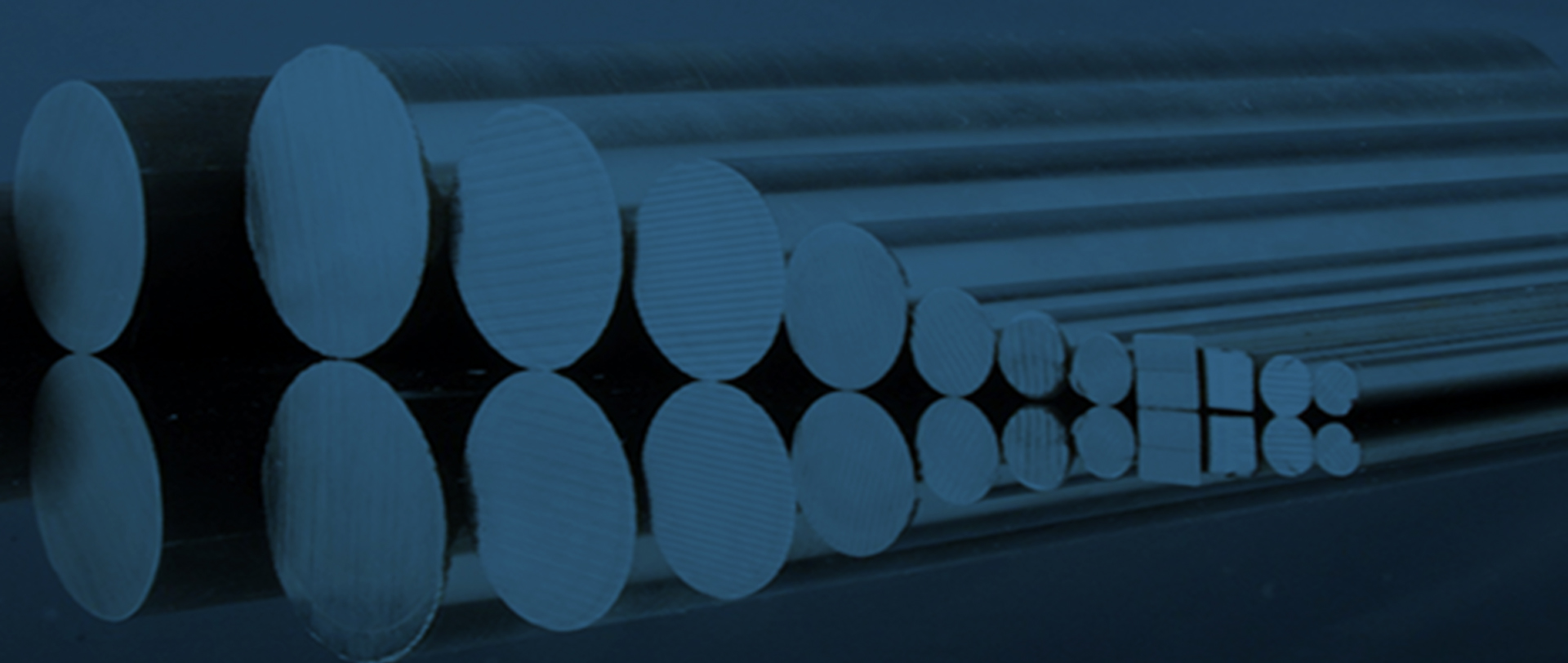

MS Rounds

MS Rounds, or Mild Steel Rounds, are cylindrical rods made of mild steel, a very malleable alloy. Produced through hot or cold rolling processes, these solid steel bars are available in various diameters and lengths. They are known for their durability and corrosion resistance, and are widely used in applications across various industries such as manufacturing and engineering.

FEATURES

Material

MS Rounds are made using MS Billets.

Size

MS Rounds are available in a vast range of sized from 24-80mm

Standards

MS Rounds conform to IS Standards and are also available in customer specifications.

APPLICATIONS

Machinery Components

MS Rounds are extensively used to manufacture various machine components such as shafts, spindles, axles, and gears. Their high strength-to-weight ratio and machinability make them ideal for these applications.

Tool and Die Making

MS Rounds are used to create tools and dies for various manufacturing processes, including forging, stamping, and extrusion. Their durability and ability to withstand high pressures and temperatures make them suitable for these demanding applications.

Precision Engineering

MS Rounds are used in precision engineering applications, such as the manufacturing of jigs, fixtures, and gauges. Their high accuracy and dimensional stability make them suitable for these applications.

Nut and Bolt Making

MS Rounds are the primary raw material for manufacturing nuts and bolts. They are cut into appropriate lengths and then threaded using specialised machines to create these essential fasteners.

Railway point and cross assemblies

MS Rounds are essential for railway point and cross assemblies. They are used to make key components like switchblades, stock rails, connecting rods, and clamps, ensuring smooth and safe train operations.

Automobile manufacturing

MS Rounds are vital in the automotive industry, used to manufacture critical components like engine parts (connecting rods, camshafts), transmission components (gears, shafts), chassis components (frames, suspension parts), and structural body reinforcements. Their high strength-to-weight ratio and machinability make them ideal for these applications.

QUALITY ASSURANCE

At every stage of production, we prioritise quality to deliver products and services that meet or exceed industry standards. Our commitment to quality assurance includes-:

Raw Material Inspection

Raw materials are thoroughly inspected to ensure quality is maintained.

In-Process Testing

Regular testing during the manufacturing process to verify adherence to specifications.

Final Inspection

Comprehensive quality checks on finished products, including dimensions, surface finish, and mechanical properties.

Certifications

Our products are certified in terms of quality and performance.

AFTER-SALE SERVICES

We are committed towards providing dedicated customer support at every stage of the purchase journey

Accountability

We assume full responsibility for any quality deficiencies and commit to prompt resolution.

Customer Support

Our dedicated support team is available to address any inquiries or concerns.

Choose Nirmal MS Rounds for your diverse needs, knowing that it is a reliable, versatile, and performance-driven solution. With a commitment to quality, precision manufacturing, and comprehensive after-sale support, Nirmal MS Rounds will meet and exceed your expectations in a wide range of applications.