Reliable

Cable Armoring Wire

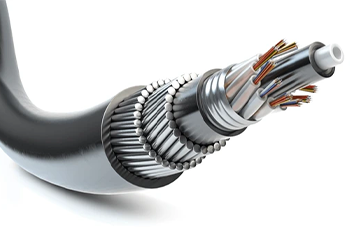

Cable Armoring wires safeguard cables from damage, environmental factors, and interference. Made of high-tensile materials like galvanized steel, they are wound or braided around the cable, providing robust protection. This enhances durability, resistance to impact, abrasion, and rodent damage. It also shields against EMI/RFI, ensuring optimal signal transmission. The wire's design balances protection and flexibility for diverse installations.