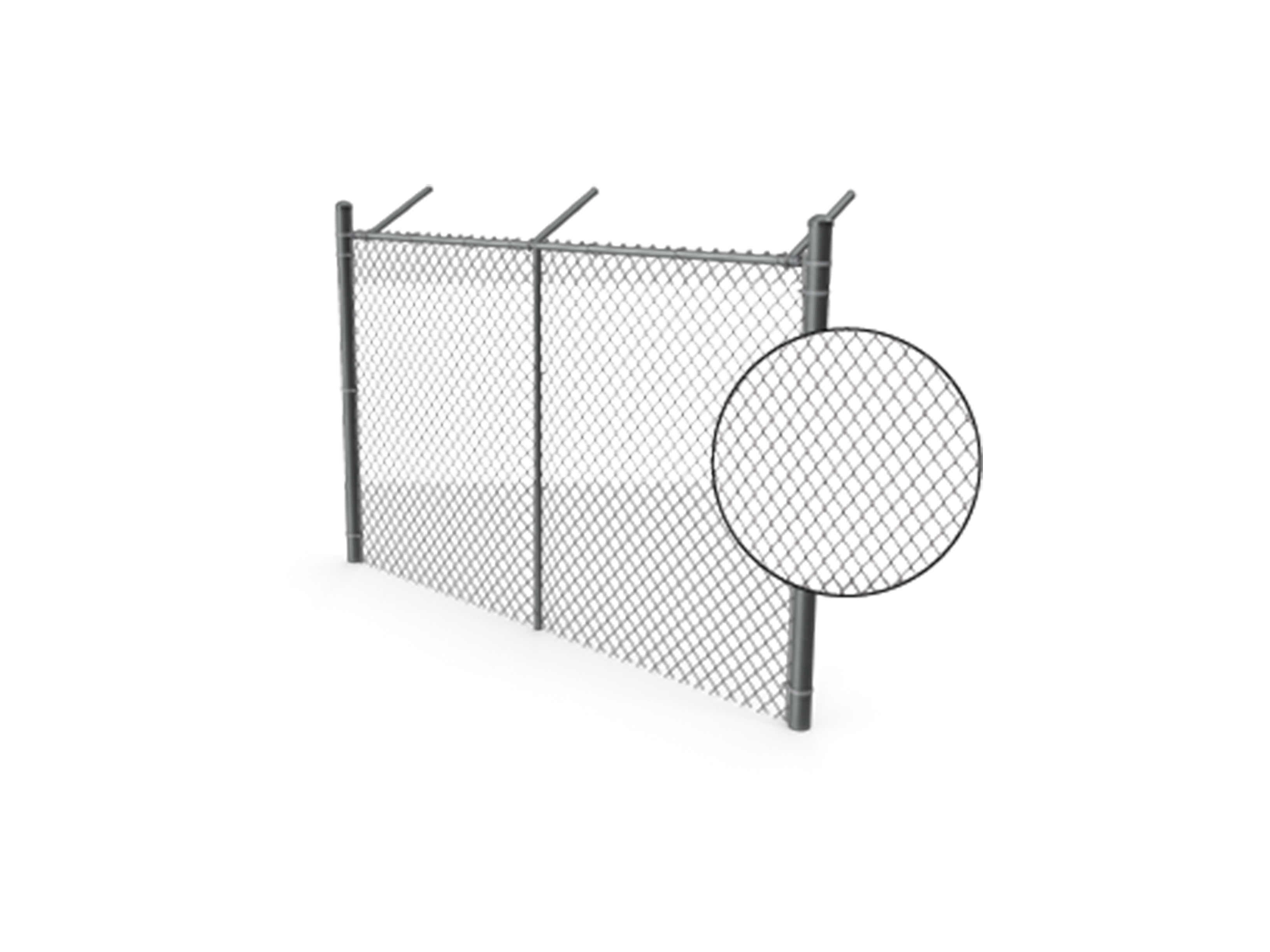

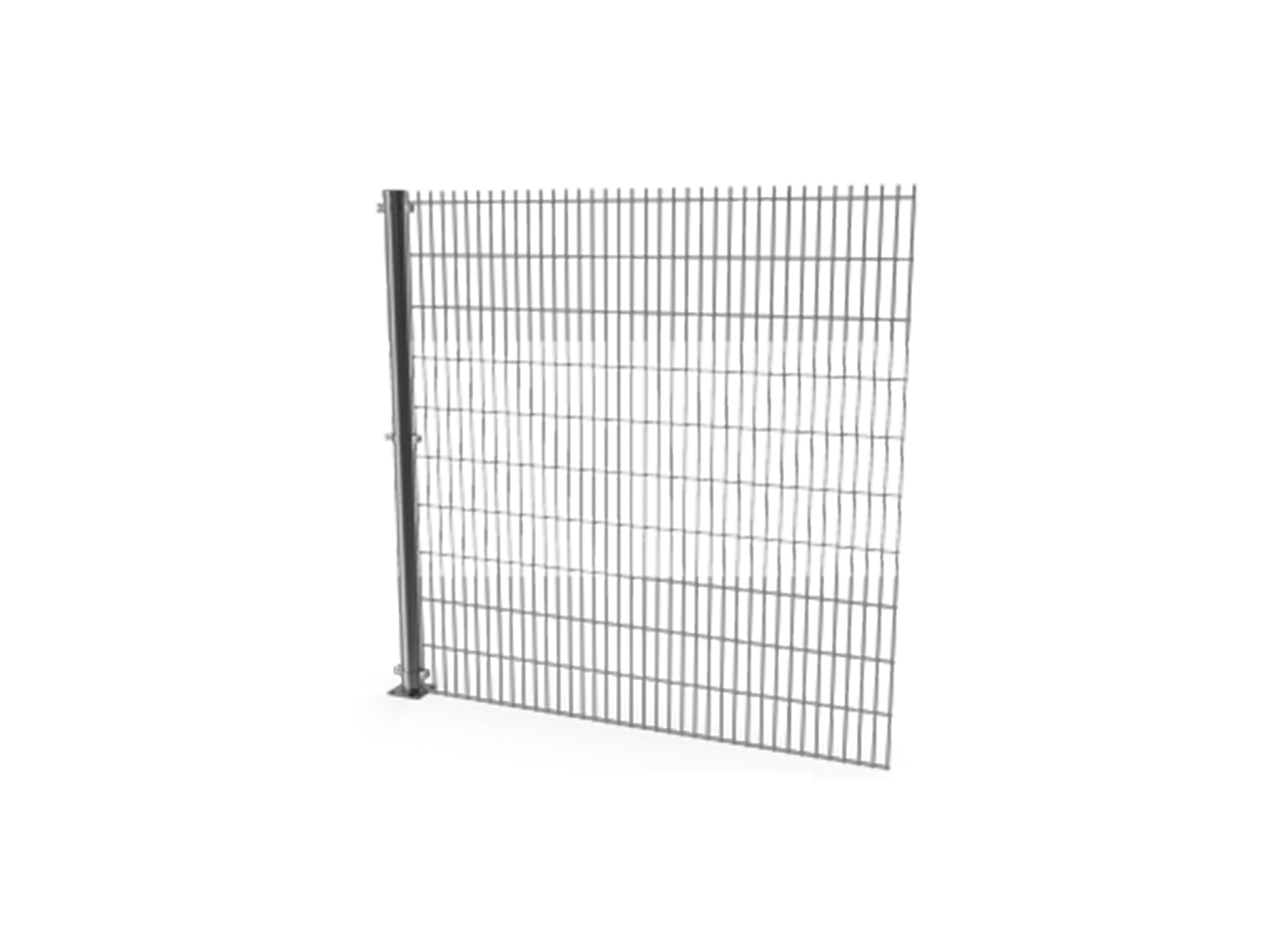

MILD STEEL WIRE

for Construction

Mild steel wires, made using low carbon steel, are renowned for their excellent ductility, tensile strength, and formability. They are available in various diameters and lengths and exhibit superior weldability and a smooth surface finish. Their consistent quality and cost-effectiveness make them a preferred choice for numerous industrial and construction applications.