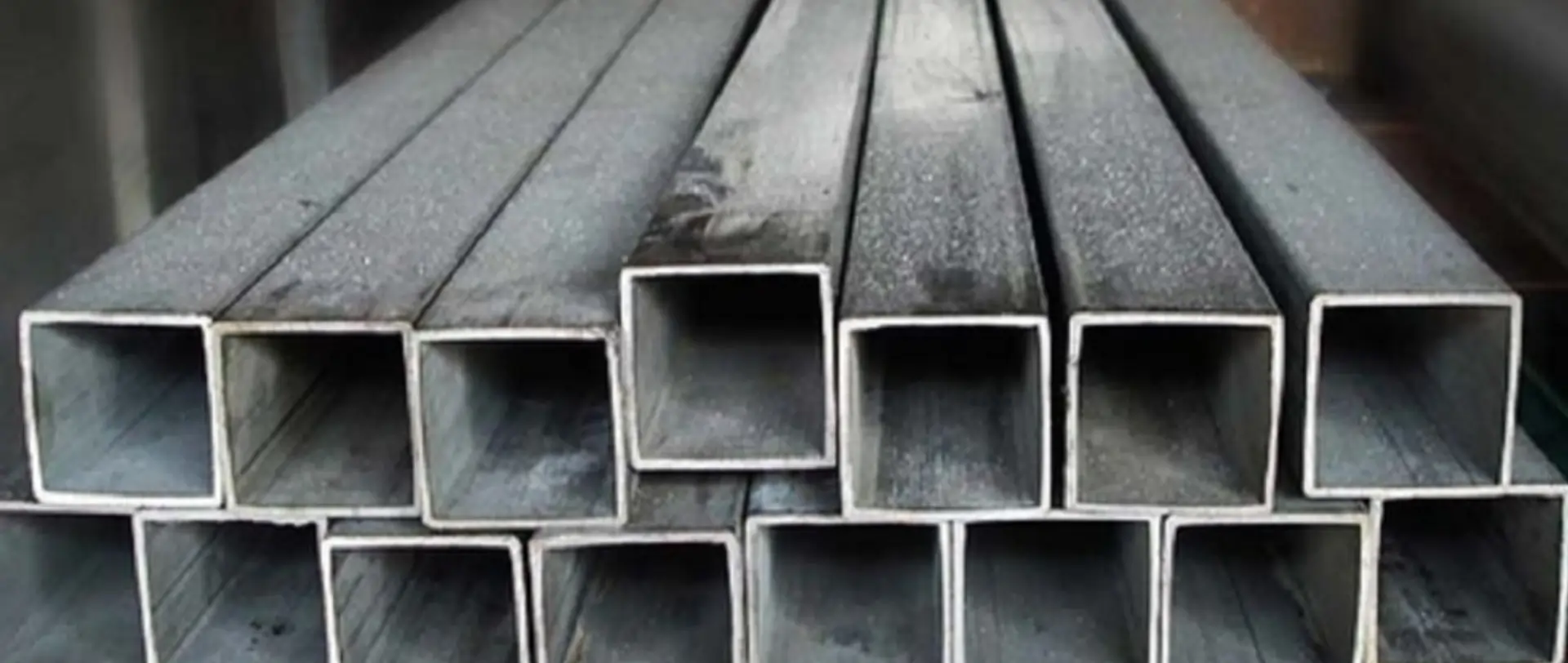

MS Square bars

MS Square Bars are versatile steel bars with a uniform square cross-section. Rolled to perfection, they are available in a wide range of sizes, measured in millimetres. These steel bars offer excellent mechanical properties such as high tensile strength and good ductility, making them suitable for various applications. Their precise dimensions and smooth finish ensure ease of use and fabrication.