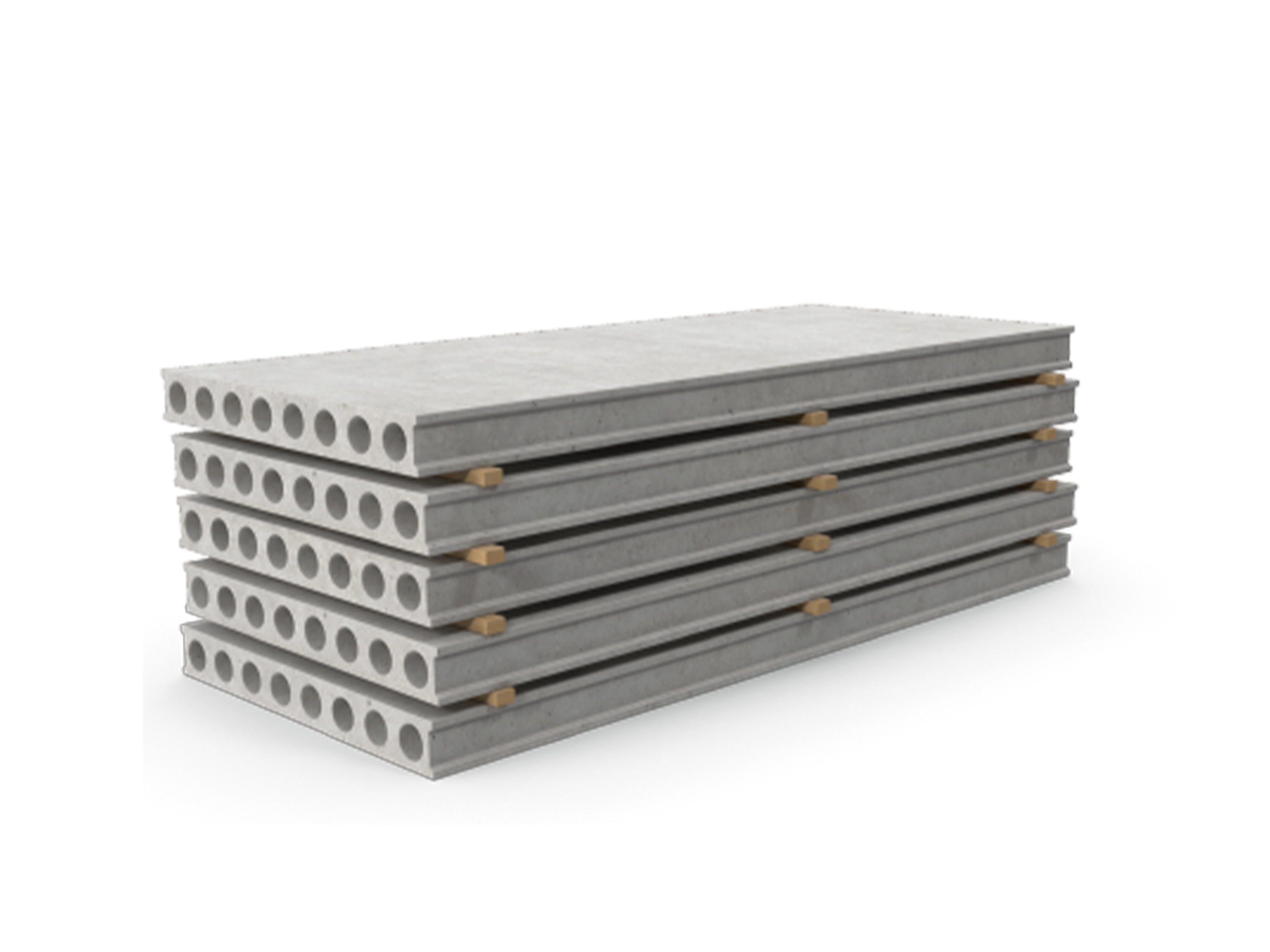

Prestressed

Concrete PC WIRE

Prestressed Concrete Wire (PC Wire) is a high-tensile steel wire used to reinforce concrete structures. Manufactured through a rigorous process of cold drawing and heat treatment, it offers high strength and low relaxation. A phosphate coating enhances its durability and bond strength with concrete. PC Wire is essential in applications requiring high tensile strength and stress distribution, ensuring long-term structural integrity.