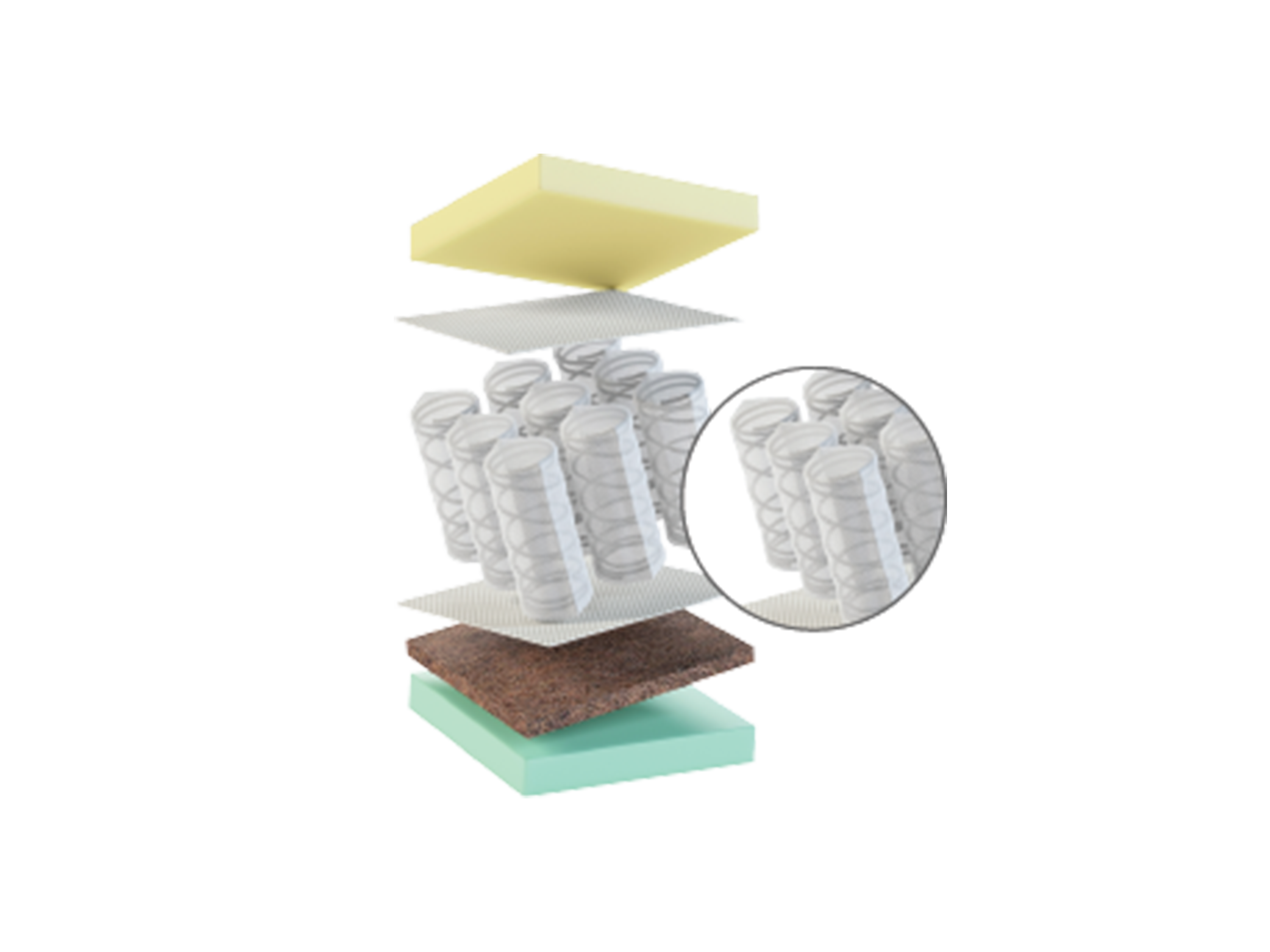

Flexible

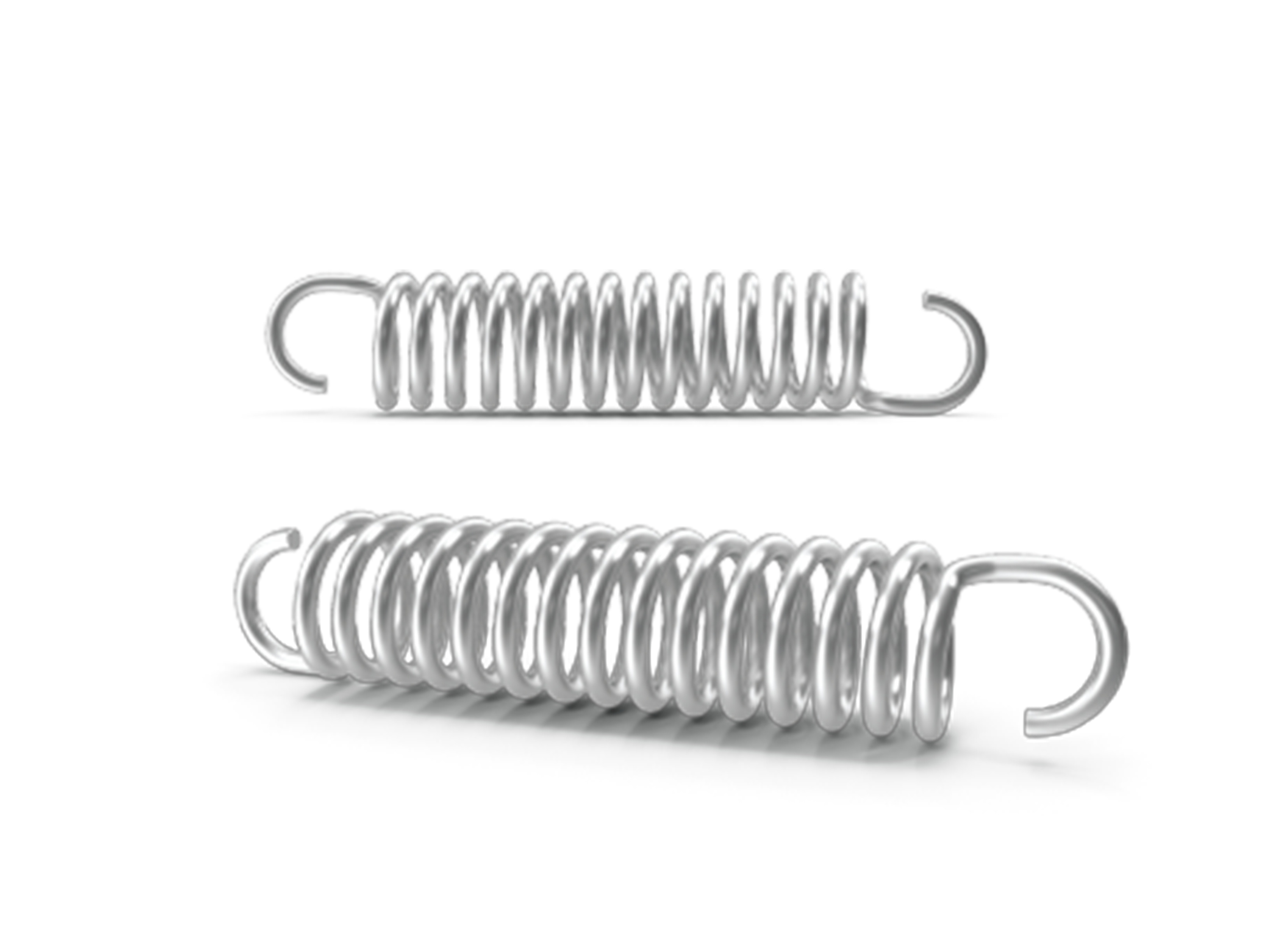

SPRING STEEL WIRE

Crafted from unalloyed high carbon steel, spring steel wires undergo a rigorous cold drawing process to achieve their exceptional properties. This process enhances the wire's strength, hardness and fatigue resistance which makes it ideal for demanding applications. Spring steel wires are an essential for manufacturing components like cold-formed helical springs, spring rings, and wire forms. Their application extends to a diverse range of industries such as automotive, cycling, and general industrial equipment.