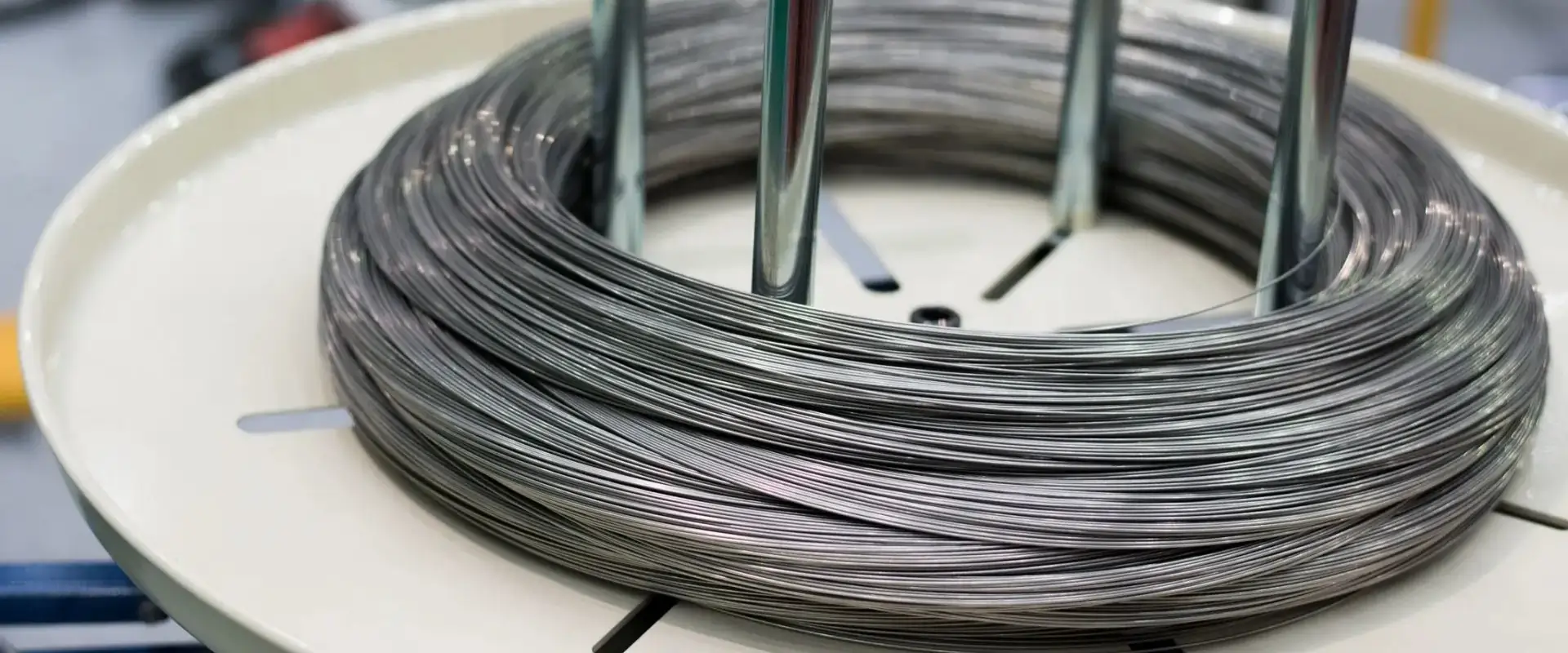

Zinc wire is a slender, ductile metallic filament composed primarily of...

Zinc-aluminium wires are a composite material that combine...

Zinc rods are cylindrical metallic bars primarily composed of zinc...

The lightweight, portable zinc metalizing spray machine simplifies...

Got questions? We've covered the essentials here.

Group Nirmal offers a wide range of zinc wires and allied products, ideal for galvanizing, thermal spraying, and corrosion protection. These wires are widely used in steel structures, marine applications, and automotive parts to create long-lasting protective coatings. Our zinc wires ensure uniform flow and coating, with excellent adhesion properties. Precision-drawn and quality-tested, they are suitable for manual and automated processes.

The zinc alloy formulation enhances wear resistance and minimizes oxidation in extreme conditions. Whether you're looking to extend product life or meet anti-corrosion compliance, Group Nirmal's zinc solutions deliver reliability and value.